Iintonga zeCarbide eqinileyo

![]() Ukuqaliswa kweeCarbide Rods eziqinileyo

Ukuqaliswa kweeCarbide Rods eziqinileyo

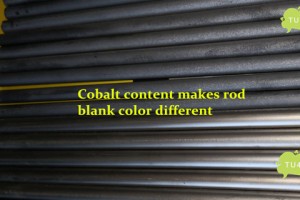

Intonga ye-carbide eqinileyo yenziwa kakhulu nge-tungsten carbide, ibinder cobalt yentsimbi kunye nezinye izinto ezenziwayo ezongezwe njengoko ifomula ifuna, ngokusebenzisa umxube wezinto, ukukhupha, uku-pre-sinter, inkqubo yokuguqula imilo emva koko yenziwe ngoxinzelelo oluphantsi. Ngabalinganiswa bokuqaqadeka okuphezulu, amandla aphakamileyo, uzinzo lweekhemikhali, ukwanda kokuqina okwandayo, ukuqhuba ngombane kunye nokuhambisa ubushushu, iintonga ze-tungsten ze-carbide zisetyenziswa ngokubanzi kwindawo yokwenza imveliso, umzekelo, ukwenza ukubhola okuncinci kwimveliso ye-PCB, ibha ye-electrode kuluntu olubonakalayo Umzi mveliso, ukubhola, isitokhwe sokumba, incam, ukutyhala, ukunxiba iinxalenye ezichanekileyo, i-CNC reamer kunye neebhloko ezinomngxunya opholileyo kumzi mveliso wokuchwetheza.

Njengendawo yokugcina ikhabhayithi, Toonney tungsten mveliso yesinyithi uvelisa uluhlu olukhulu lwe-tungsten alloy kubandakanya iintonga eziqinileyo, iintonga ezinomngxunya othe ngqo / ojikelezayo, iintonga ezimile ngokwemfuno zabathengi kunye ne-T emiselweyo njl.

Iintonga ze-carbide eziqinileyo, akukho mibhobho ipholileyo ngaphakathi. Sinezinto ezili-10 zefomula yezinto ezisetyenziswa kakhulu, umzekelo, iintonga ze-PCB micro drill, i-micro milling cutter, i-carbide saw blade, i-drill to machining aluminium alloy, i-alloy base alloy, i-alloy base alloy kunye; I-wolfram carbide njlnjl.

I-Wolfram carbide: I-Wolfram carbide sisixhobo esidityaniswa yi-wolfram kunye ne-carbide. Yikristale emnyama enamacala amathandathu kunye ne-metallic luster, apho ubunzima bayo bufana nedayimani.Wolfram khabhayithi ngumqhubi olungileyo wombane kunye nobushushu, awunakunyibilika emanzini, ihydrochloric acid okanye isulfuric acid, kodwa ngokulula inyibilika kwisisombululo esixubeneyo se-nitric acid kunye ne-hydrofluoric acid. I-wolfram carbide echanekileyo ibuthathaka, kodwa ukongeza i-titanium okanye i-cobalt kunye ne-sintered, i-roughness iya kuba phezulu kakhulu. I-Wolfram carbide ikwabizwa ngokuba yi-tungsten carbide.

Isinyithi seTungsten / isinyithi seTungsten:I-Tungsten ikwabizwa ngokuba yi-wolfram, eyona fomu yesinyithi ye-tungsten kwisicelo semizi-mveliso yi-tungsten carbide. Ifektri yentsimbi ye-Toonney ivelise i-carbide rods eqinile iminyaka emininzi kwaye ifumana igama elihle ekhaya nakwamanye amazwe.

Iinkcukacha Packaging: Ingxowa yeplastiki, emva koko ikhuselwe kwigumbi lokulala, ekugqibeleni kwibhokisi engaphandle.

Imiba yesampulu:Iintonga zekhabhayithi eziqinileyo ezinokufumaneka kwi-inventri yethu eqhelekileyo, zinokunikwa njengeesampulu simahla. Ngeentonga ze-carbide eqinileyo kunye nomthengi okhethekileyo ofunekayo, uya kuhlawuliswa. Ewe kunjalo, abathengi kufuneka bahlawule umrhumo wokuhambisa ngenqanawe. Ngokwesiqhelo, ixesha lokuhola leesampulu liya kuba ngaphakathi kweentsuku ezi-7 zokusebenza.

Ubuncinci be-Order Order: Akukho buncinci boku-odola ubungakanani beentonga ze-carbide eqinileyo kwityala lokuqala. Kodwa kwi-odolo yesibini, inani elipheleleyo leentonga ze-carbide eqinileyo kufuneka lingabi ngaphantsi kwe-1000 yeedola.

Ixesha lokuzisa: Iintsuku 7-15 zokusebenza

![]() Izixhobo zokusika iBakala leTafile kunye nokuSebenza

Izixhobo zokusika iBakala leTafile kunye nokuSebenza

| IBakala | Co% | Iinkozo Siz (μm) | Ukuxinana (g / cm3) | Ukuqina (HRA) | I-TRS (N / mm2) |

| TU90 | 9.0 | 0.2 | 14.35 | 94.1 | 5200 |

| TF06 | 6.0 | 0.6 | 14.81 | 93.1 | 4000 |

| TU06 | 6.0 | 0.4 | 14.8 | 94.3 | 4600 |

| TU08 | 8.0 | 0.4 | 14.52 | 93.5 | 4800 |

| TU08S | 8.0 | 0.3 | 14.5 | 93.6 | 5000 |

| TU40 | 10.0 | 0.8 | 14.4 | 91.7 | 4600 |

| TU40F | 10.0 | 0.6 | 14.45 | 92.3 | 4600 |

| TU40S | 10.0 | 0.5 | 14.5 | 92.5 | 4800 |

| TU44 | 12.0 | 0.4 | 14.1 | 92.6 | 4800 |

| TU25 | 12.0 | 0.6 | 14.06 | 92.5 | 4200 |

| TU45 | 13.0 | 0.3 | 13.95 | 92.7 | 4800 |

| TU55 | 13.0 | 0.3 | 13.92 | 92.6 | 4800 |

![]() Isicelo esiCetywayo

Isicelo esiCetywayo

| IBakala | Isicelo esicetyiswayo |

| TU90 | Izixhobo zokusika izixhobo zomatshini oqingqiweyo (HRC65-70), umthi onzima kunye nabasiki beepolishi eziphezulu. Zintle for mgawuli gqiba machining 316L stinless intsimbi |

| TF06 | Kuba izixhobo ukusika machining aluminium wemagniziyam ingxubevange, grafayithi kunye ifayibha edityanisiweyo. |

| TU06 | I-PCB ye-micro-drill kunye ne-end machining ephezulu. |

| TU08 | Kuba PCB micro-ukuzama, mgawuli mgawuli mini. |

| TU08S | Ukubhola kwe-PCB encinci, izixhobo zokusika i-finis machining izixhobo ezicinywayo (HRC60-65), i-316L intsimbi engenasici, iphepha lokunyibilikisa iphepha kunye nephepha lesinyithi leemoto. |

| TU40 | Kuba bit ukuzama eqhelekileyo, ekupheleni lokusila kunye Ukuhlukunyezwa die. |

| TU40F | Kuba bit ukuzama eqhelekileyo, isiphelo lokusila machining titanium ingxubevange, intsimbi engatyiwa kunye engwevu uphose intsimbi. |

| TU40S | Izixhobo zokusika machining i-316L intsimbi engenasici, eyona nto ilungileyo yezixhobo zesetyhula eziqhelekileyo. |

| TU44 | Izixhobo zokusika izixhobo ze-titanium alloy, i-alloy enganyangekiyo ngobushushu, i-stainless steel, i-quesnched steel (HRC55 nangaphezulu), i-iron cast iron. |

| TU25 | Izixhobo zokusika izixhobo zokuchwela ubushushu bentsimbi (Ukuqina kwe-HRC45 nangaphezulu), isinyithi, intsimbi engenasici. |

| TU45 | Izixhobo zokusika i-titanium, i-alloy enganyangekiyo ngobushushu, i-stainless steel, i-quesnched steel (HRC60 nangaphezulu) |

| TU55 | Ibanga elinobunzima obuphezulu obomvu, elungileyo ukusika izixhobo machining ubushushu obuphezulu obunganyangekiyo, intsimbi ecinywayo (HRC60 nangaphezulu) kunye ne-titanium alloy |

![]() Ukucaciswa kweCarid Carbide Rods

Ukucaciswa kweCarid Carbide Rods

| Dia. Ø mm |

Ukunyamezelana. (Mm) | Ubude (mm) | Tol. (Mm) | Dia.Ø (mm) | Ukunyamezelana. (Mm) | Ubude (mm) | Tol. (Mm) |

| 2.0 | + 0.30 / + 0.15 | 330 | 1.5 | 16.5 | + 0.8 / + 0.3 | 330 | 1.5 |

| 2.5 | + 0.30 / + 0.15 | 330 | 1.5 | 17.0 | + 0.8 / + 0.3 | 330 | 1.5 |

| 3.0 | + 0.50 / + 0.30 | 330 | 1.5 | 17.5 | + 0.8 / + 0.3 | 330 | 1.5 |

| 3.5 | + 0.50 / + 0.30 | 330 | 1.5 | 18.0 | + 0.8 / + 0.3 | 330 | 1.5 |

| 4.0 | + 0.50 / + 0.30 | 330 | 1.5 | 18.5 | + 0.8 / + 0.3 | 330 | 1.5 |

| 4.5 | + 0.50 / + 0.30 | 330 | 1.5 | 19.0 | + 0.8 / + 0.3 | 330 | 1.5 |

| 5.0 | + 0.50 / + 0.30 | 330 | 1.5 | 19.5 | + 0.8 / + 0.3 | 330 | 1.5 |

| 5.5 | + 0.50 / + 0.30 | 330 | 1.5 | 20.0 | + 0.8 / + 0.3 | 330 | 1.5 |

| 6.0 | + 0.50 / + 0.30 | 330 | 1.5 | 20.5 | + 0.8 / + 0.3 | 330 | 1.5 |

| 6.5 | + 0.50 / + 0.30 | 330 | 1.5 | 21.0 | + 0.8 / + 0.3 | 330 | 1.5 |

| 7.0 | + 0.50 / + 0.30 | 330 | 1.5 | 21.5 | + 0.8 / + 0.3 | 330 | 1.5 |

| 7.5 | + 0.50 / + 0.30 | 330 | 1.5 | 22.0 | + 0.8 / + 0.3 | 330 | 1.5 |

| 8.0 | + 0.50 / + 0.30 | 330 | 1.5 | 22.5 | + 0.8 / + 0.3 | 330 | 1.5 |

| 8.5 | + 0.50 / + 0.30 | 330 | 1.5 | 23.0 | + 0.8 / + 0.3 | 330 | 1.5 |

| 9.0 | + 0.60 / + 0.30 | 330 | 1.5 | 23.5 | + 0.8 / + 0.3 | 330 | 1.5 |

| 9.5 | + 0.60 / + 0.30 | 330 | 1.5 | 24.0 | + 0.8 / + 0.3 | 330 | 1.5 |

| 10.0 | + 0.60 / + 0.30 | 330 | 1.5 | 24.5 | + 0.8 / + 0.3 | 330 | 1.5 |

| 10.5 | + 0.60 / + 0.30 | 330 | 1.5 | 25.0 | + 0.8 / + 0.3 | 330 | 1.5 |

| 11.0 | + 0.60 / + 0.30 | 330 | 1.5 | 25.5 | + 0.8 / + 0.3 | 330 | 1.5 |

| 11.5 | + 0.60 / + 0.30 | 330 | 1.5 | 26.0 | + 0.8 / + 0.3 | 330 | 1.5 |

| 12.0 | + 0.60 / + 0.30 | 330 | 1.5 | 26.5 | + 0.8 / + 0.3 | 330 | 1.5 |

| 12.5 | + 0.60 / + 0.30 | 330 | 1.5 | 27.0 | + 0.8 / + 0.3 | 330 | 1.5 |

| 13.0 | + 0.60 / + 0.30 | 330 | 1.5 | 27.5 | + 0.8 / + 0.3 | 330 | 1.5 |

| 13.5 | + 0.60 / + 0.30 | 330 | 1.5 | 28.0 | + 0.8 / + 0.3 | 330 | 1.5 |

| 14.0 | + 0.70 / + 0.30 | 330 | 1.5 | 28.5 | + 0.8 / + 0.3 | 330 | 1.5 |

| 14.5 | + 0.70 / + 0.30 | 330 | 1.5 | 29.0 | + 0.8 / + 0.3 | 330 | 1.5 |